Qingdao Chaofeng Plastic Machinery Co., Ltd. specializes in producing PVC crust foam board production line, PVC crust foam board extruder

Qingdao Chaofeng Plastic Machinery Co., Ltd. specializes in the production of PVC crust foam board production line. Production parameters of PVC foam board production equipment:

Automatic feeding and drying system to ensure dry materials and ensure product quality

Automatic temperature controller with PID adjustment function, making temperature control more accurate ± 2 ° C

Barrel heating system with air cooling device to reduce temperature error

The application of double-station hydraulic quick change screen device (1.5 sec/time) realizes non-stop screen change and continuous production

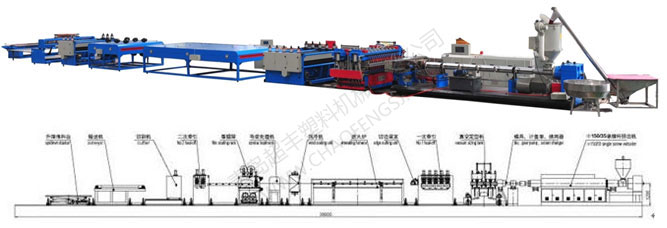

The plastic extruder adopts single, two and three extruders for simultaneous extrusion, plastic melt distributor compounding and extrusion die multi-channel compounding, and is used for producing single-layer and multi-layer composite sheet and so on. Model selection

The selection of the plastic melt metering pump makes the plastic melt extrusion more stable and ensures the uniformity of the product.

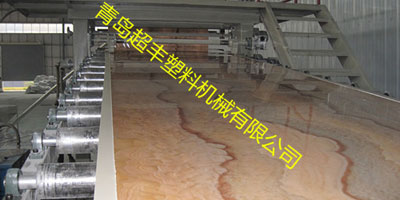

The calender roll of PVC foam board production equipment adopts advanced processing technology to ensure the accuracy of the roll and the requirements for producing high quality plastic sheet products.

The calender roll transmission of the production equipment is a single-roller independent transmission form; the independently controlled roll temperature adjustment system can precisely control the temperature of the calender roll to make the sheet thickness uniform

The cutting of the product adopts the automatic fixed length cutting device to ensure that the diagonal dimension of the sheet is accurate within 3mm.

Production of plastic PVC foam board sheet width within 3m; thickness of 0.3-20mm for a variety of models to choose from

The whole machine adopts DC or variable frequency speed regulation and selected electronic control system to realize monotonous and group control linkage, precise, stable and reliable control, and simple process operation.

Three-roller type: vertical, 45° inclined, horizontal for optional use: This production line is suitable for the production of PP, PE, PC, PS, ABS, PVC, PMMA, PET, HIPS and other plastic sheet products Composition: plastic extruder, dry feeding system, machine head and hydraulic screen changer, three-roll calender, cooling setting bracket, cutting device, tractor, cutting and shearing machine, conveying material table, roller temperature Adjustment system, electric cabinet.

Product features and functions

· PVC crust foam board, with sound insulation, sound absorption, heat insulation, insulation and other properties.

·The board is flame retardant, self-extinguishing and safe to use.

·All series of products have the properties of moisture proof, mildew proof and non-absorbent, and the shockproof effect is good.

· After the series of products are made of weather resistant formula, the color can be unchanged for a long time and it is not easy to age. The product is light in texture, convenient for storage, transportation and construction.

· This product can be constructed using general woodworking tools.

· Can be drilled, sawed, nailed, planed, glued, etc. like wood.

· Suitable for thermoforming, heating bending and folding processing.

· Can be welded according to the general welding procedure, and can also be bonded with other PVC materials.

· This product has a smooth surface and is also printed. (To clean the surface before printing).

Product Usage

Transportation industry: ships, airplanes, buses, train cars, roofs, car cores, interior panels.

Construction and decoration industry: building exterior wall panels, interior decorative panels, residential, office, public building partitions, commercial decorative frames, clean room panels, ceiling panels.

Advertising industry: stencil printing, computer lettering, advertising signs, display boards, sign boards.

Industrial applications: chemical industry anti-corrosion engineering, thermoformed parts, cold storage panels, special cold preservation projects, environmental protection panels.

Other uses: formwork, sports equipment, aquaculture materials, beach moisture-proof facilities, water-resistant materials, art materials, various lightweight partitions

Technical Parameters

Test items | unit | Test results |

Apparent density | g/cm3 | 0.5-0.8 |

Tensile Strength | MPa | 12-20 |

Bending strength | MPa | 12-18 |

Flexural modulus | MPa | 800-900 |

Impact strength | KJ/m2 | 8-15 |

Elongation at break | % | 15-20 |

Shore hardness | D型 | 45-50 |

Water absorption | % | ≥1.5 |

Vicat softening point | °C | 73-76 |

Flame retardancy | Self-extinguishing from fire less than 5 seconds |

PVC wood-plastic building formwork equipment, PVC wood-plastic sheet production line, detailed description: The superiority of wood-plastic building formwork compared with traditional building formwork:

1. Environmental protection. Both timber resources and steel resources are non-renewable resources, and the state will control them more and more strictly, which is reflected in the continuous rise in prices. The raw materials used in the wood-plastic building formwork are waste plastics and discarded wood materials. It is the recycling of waste and contains no harmful chemicals such as formaldehyde. It will be favored by the government and market in the near future.

2, recycling. The traditional building formwork becomes solid waste after the damage is used, which increases environmental pollution. The wood-plastic building formwork can be recycled and re-processed, that is, the damaged wood-plastic building formwork can be crushed and then put into the processing machine for re-engineering to form a brand-new product.

3. The number of cycles is long. The number of cycles of wood formwork is 3 to 4 times, and the number of cycles of wood-plastic formwork is 25 to 28 times.

4, the intensity is large. The strength of the wood-plastic building formwork is 8-10 times that of the wood formwork, and it can fall from a height of 3 to 4 meters without being damaged or deformed. It does not absorb water, is not layered, and is easy to release.

5, other features: like wood, can be sawed and nailed, easy for construction workers to install, integrate, stack; flame retardant, anti-corrosion, anti-mite, large temperature range, eliminating unnecessary losses and potential dangers

Remarks: The above specifications are subject to change without notice.

Next:PVC wave board, trapezoidal board production line